Custom components for machine construction and plant engineering

Whether they're made from PE, PA, POM or PETP, Murtfeldt components offer you maximum flexibility for the design of your production plant. Because Murtfeldt designs, configures and produces every finished part in close consultation with you. Even in the smallest of quantities.

The name Murtfeldt stands for the manufacture of custom-designed components using our extensive range of plastics. You supply us with drawings or CAD data, and we produce complex finished parts for machine construction and plant engineering using state-of-the-art production facilities. Can’t provide a technical drawing? Or need some help with developing new applications? Our Application Technology team is happy to advise you and create new drawings. We can work on and adapt your data together with you via online meetings so that we always achieve the best possible result. Our application advisers can also visit you in person at your premises if the component you need is complex and requires the compiling of specific data.

Need a custom component?

We will design and manufacture any finished part exactly according to your requirements.

Examples and application areas for Murtfeldt finished parts

We can turn our hand to anything!

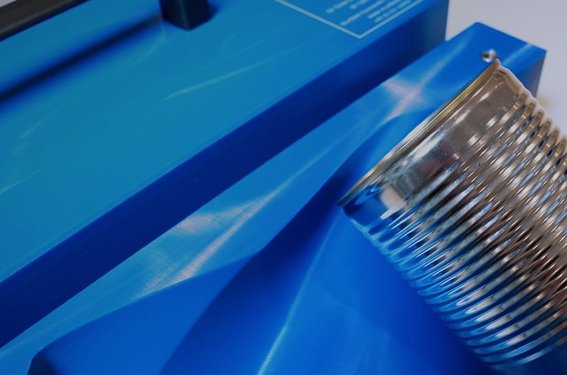

Product turners from Murtfeldt

Our custom-built turners ensure that your products are positioned precisely as required during the production process. Regardless whether it's jars, tins or folding boxes that need to be turned. We will work with you to design a product turner that is perfect for your specific requirements.

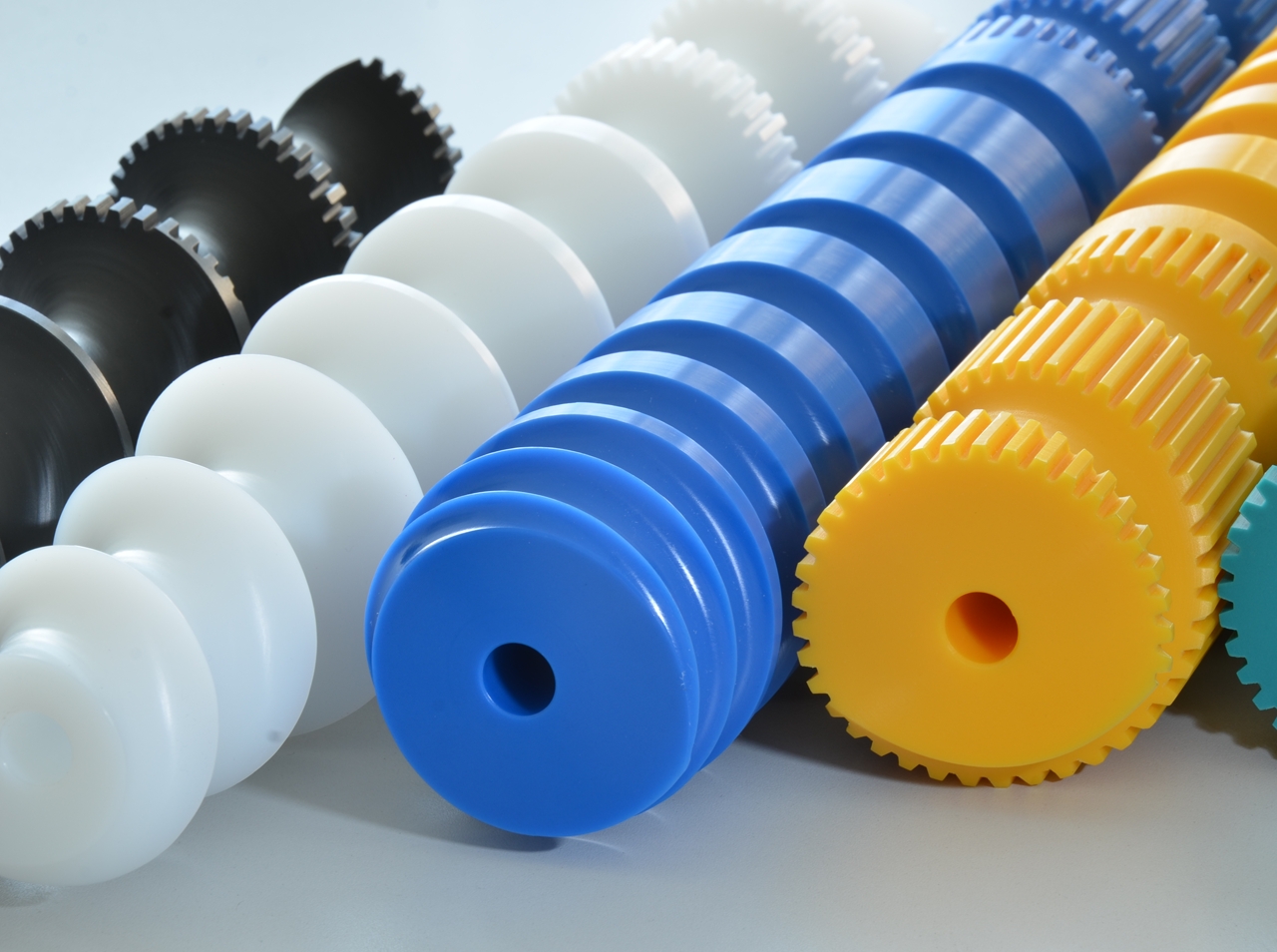

Conveying screws

Whether it's a conveying, dosing or transport screw you need, we can design it for you – precisely tailored to your measurements.

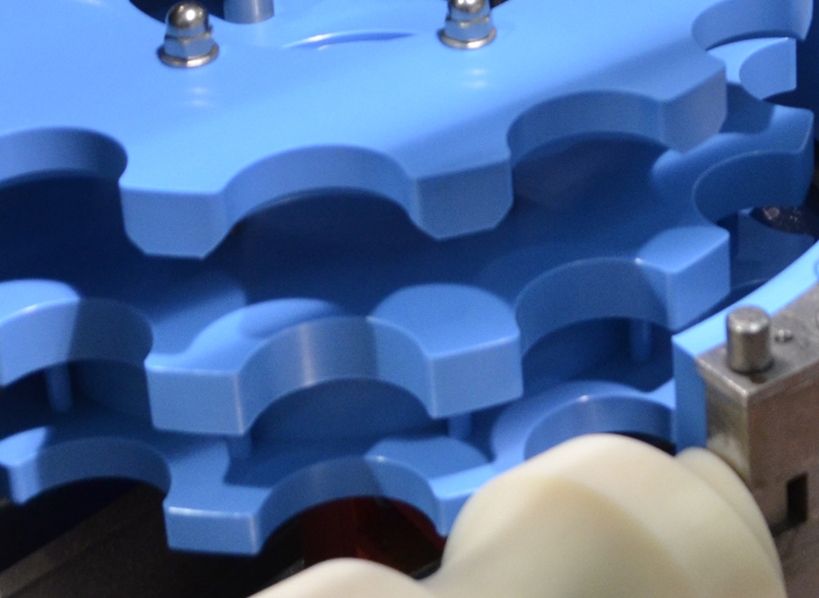

Format sets

We produce complete format sets in a wide range of dimensions according to customer specifications.

Ram guards

An extremely impact-resistant alternative to conventional ram guards made from wood or metal.

Guides and slide profiles for modular belts

Extremely wear-resistant and low-friction.

Your advantages at a glance

High-quality plastics

Manufacture of components made from PE, PA, POM, PEEK and PET (PETP).

Made to individual requirements

Production according to drawings or samples.

Small quantities

We start production at 1 piece – cost-efficient and fast.

State-of-the-art production facilities

Ultra-modern machines for diverse machining options.

State-of-the-art production facilities

Cutting, milling, turning, profiling, drilling, vibratory grinding, welding or tempering ...

... our machines and systems are state-of-the-art and cover a diverse range of machining options (X axis: up to 4000 mm / Y axis: up to 2200 mm / Z axis: up to 800 mm). This means that small quantities and even single parts can be produced in a cost-effective way. We place particular value on plastics-compatible processing. At Murtfeldt, research and application go hand in hand.

- 29 CNC milling centres

- 5 CNC universal milling machines

- 3 NC universal milling machines

- 12 CNC automatic lathes

- 5 cyclic lathes

- 5 centre lathes

- 10 coordinate drilling machines

- 7 automatic profiling machines

- 7 table undercutters

- 4 sheet splitting systems

- 4 format circular saws

- 2 four-side planers

- 3 planers

- 1 rotary planer