![[Translate to Deutsch:] individuell gefertigte produkte von murtfeldt kunststoffe. formatsätze](/fileadmin/user_upload/individuelle-bauteile/img-banner-Murtfeldt_Produkte_Fertigteile_formatsatz.jpg)

Tailored format sets

We provide comprehensive advice ranging from new designs through to the supply of replacement parts.

Murtfeldt format sets

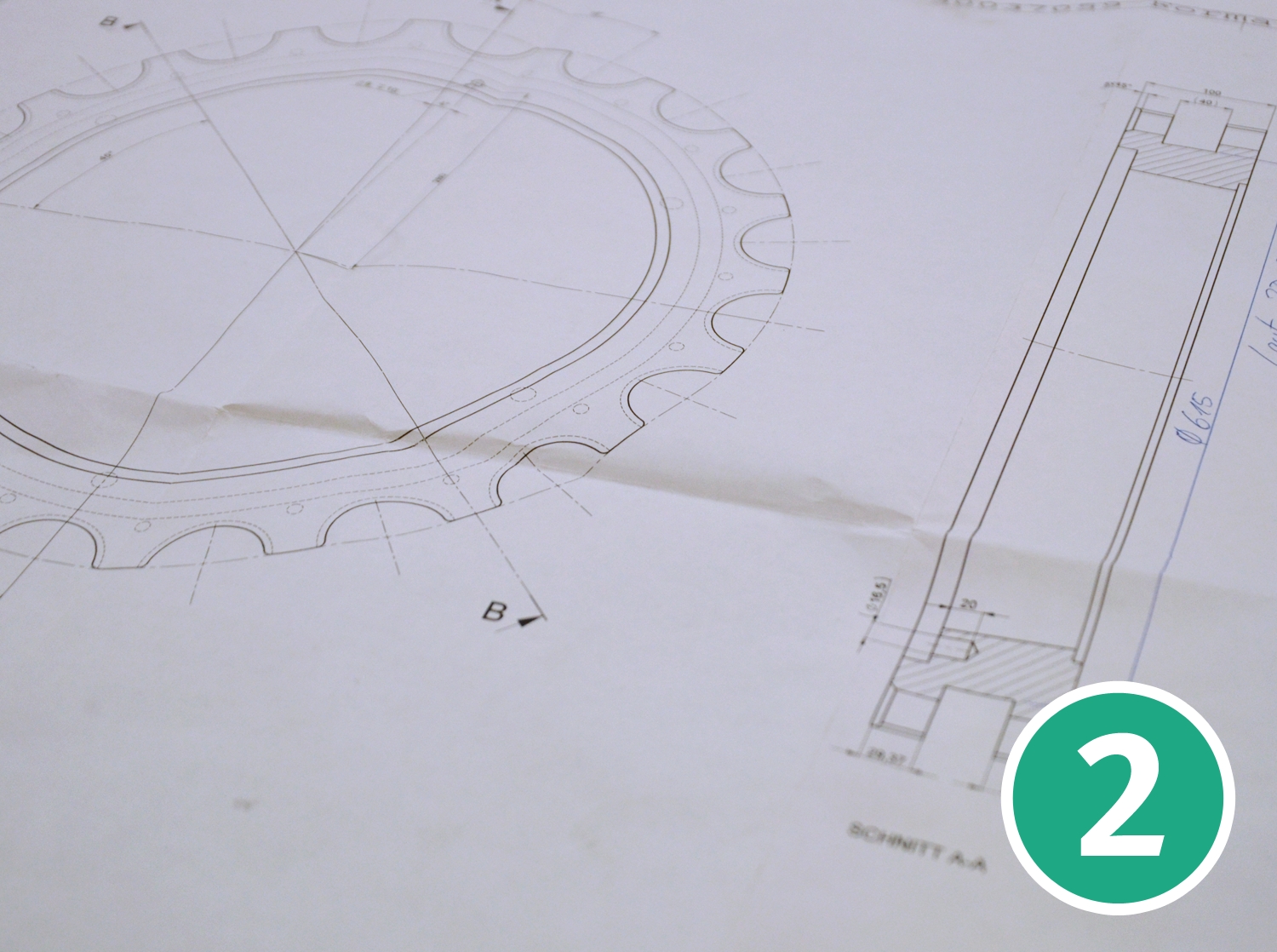

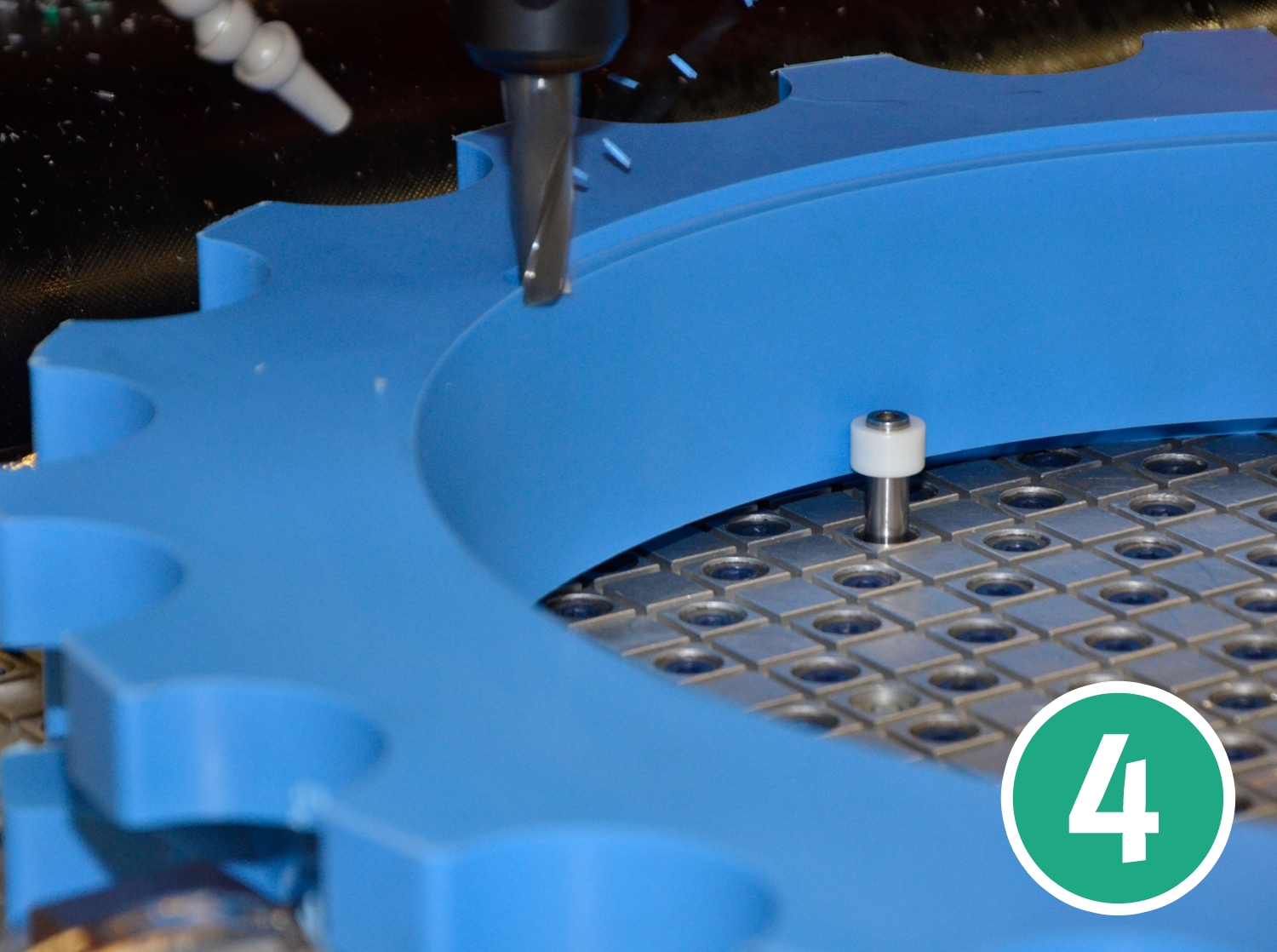

We offer you our extensive expertise for the milling of plastic format sets, also known as plastic machining, as well as the manufacture of screws. Whether you need advice on the design of a new product or on replacement parts, we are here to help.

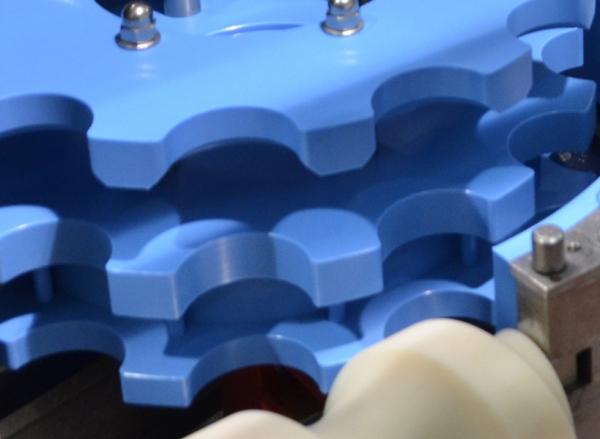

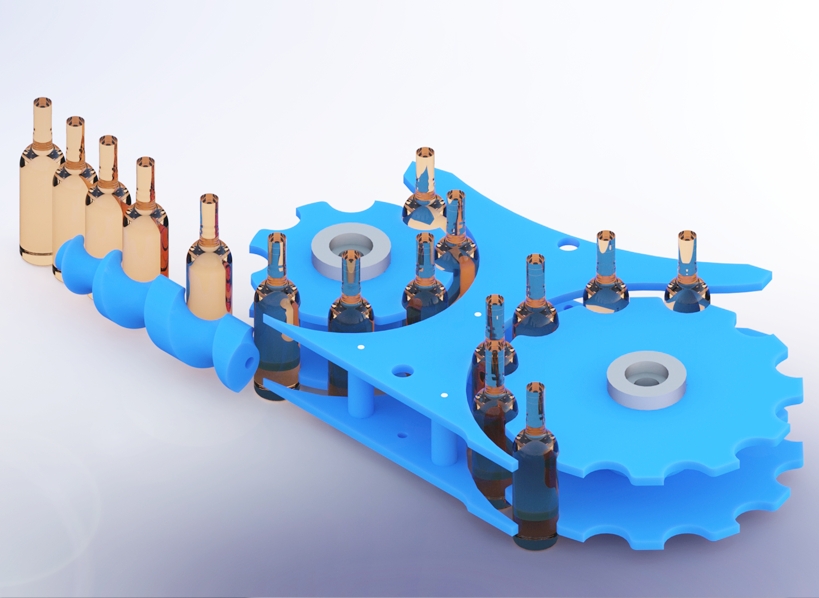

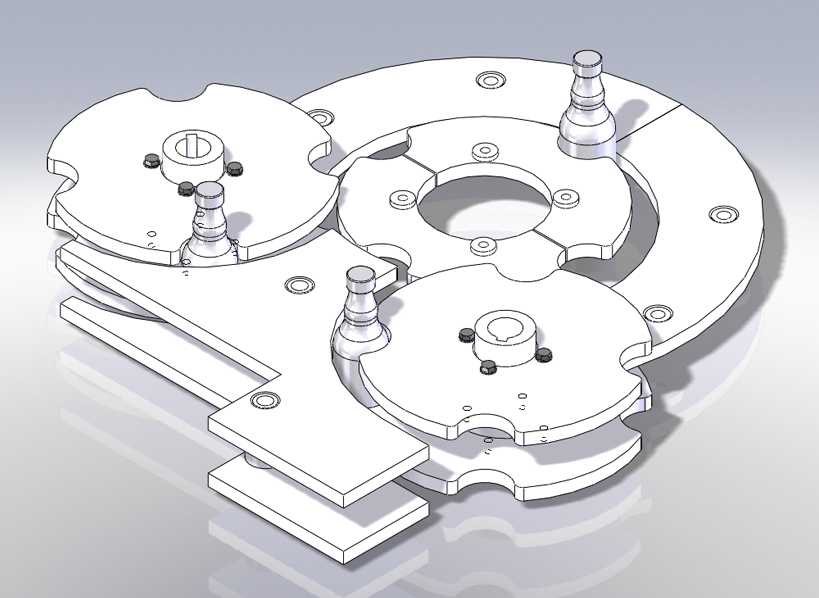

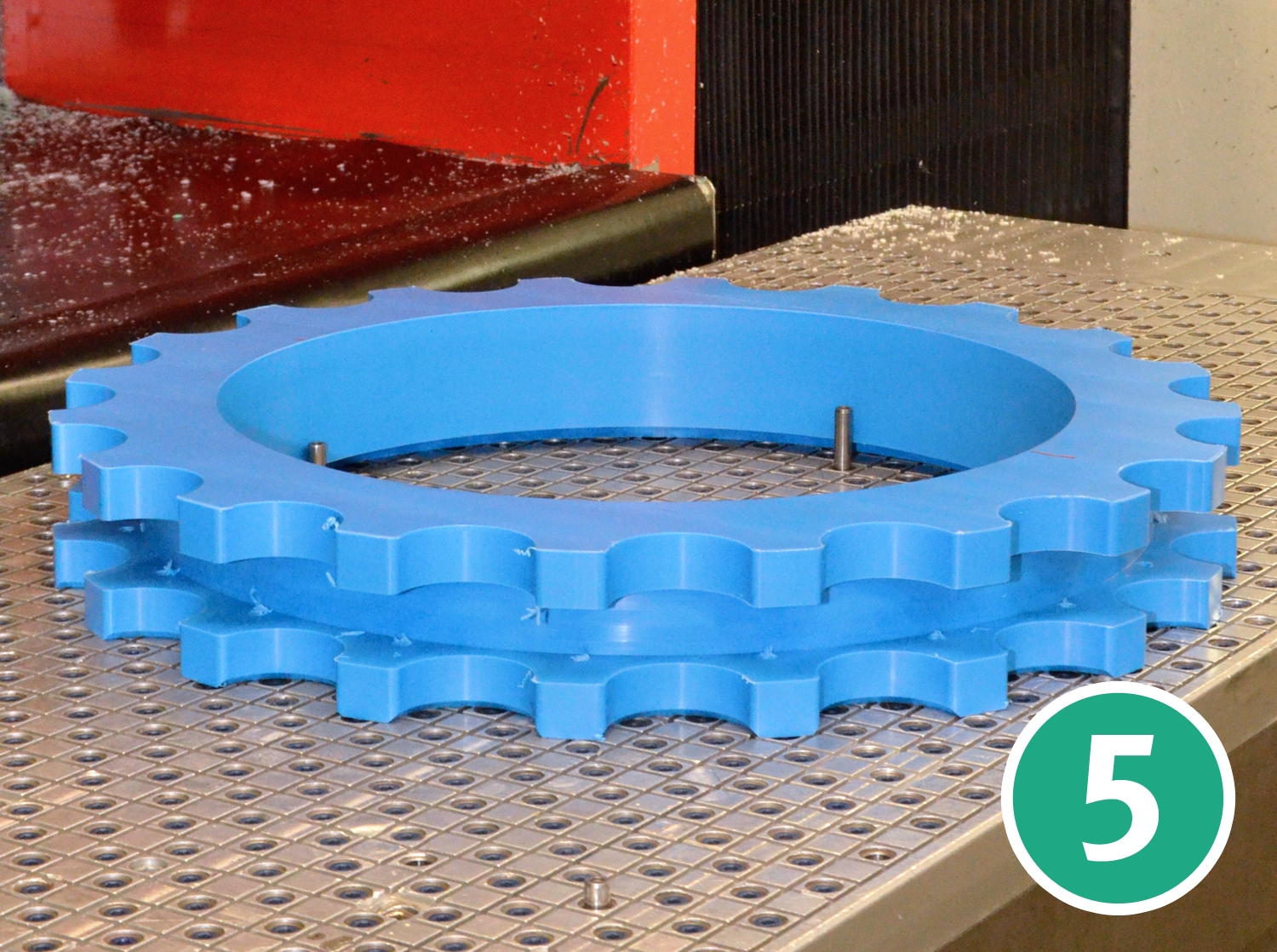

Murtfeldt format sets consist of conveying screws, conveyor stars and guide components, all manufactured from plastics included in our extensive product selection. Conveying screws are, as described on their product page, tailored exactly to the bottle shape and proportions required. Conveyor stars can be manufactured as complete units, in two parts or, for very large systems, as segments. Guide components are produced in project-specific shapes and dimensions, and on request also with replaceable slide rails. Our machining of plastics is optimised across all manufacturing processes.

We work with you to create your format set, ensuring it is precisely tailored to your needs.

Possible uses for Murtfeldt format sets

We mill complete format sets in various dimensions according to your requirements for filling plants in the food, beverage, and pharmaceutical industries – as individual units and in series production. As a plant constructor and beverage filling specialist, you are permanently confronted with the challenge of keeping your filling systems up to date and successfully meeting high global demands. Increasing filling speeds for large order quantities, for example, often requires complete new high-performance systems. If you are a medium-sized filling company, you want to benefit from technological innovations on an individual machine basis. All our customers in the food and beverage industry are subject to the demands for increased filling quality, and greater line availability, as well as reduced maintenance, energy, water and cleaning agent costs. However, these costs can increase quickly (and by as much as 20 to 30 per cent) due to strict hygiene standards, as the time and effort involved is substantial.

Reduced cleaning times with the same product quality and safety are the goal here. Our Murtfeldt product turners, format sets, and conveying and drive screws make this goal achievable for you as user. We are committed to meeting your requirements and place great importance on the selection of the right plastics. All Murtfeldt plastics are slide optimized, which significantly reduces the amount of energy necessary to achieve your desired drive performance, and also offer high abrasion resistance as well as exceptional resistance to chemicals. These plastic properties guarantee machines and plants a long service life. This in turn facilitates sustainable growth for your company, along with high energy efficiency and lower maintenance and servicing requirements

Picture gallery

Everything is possible!

Our Murtfeldt design team are happy to advise you and will, on request, create your format set tailored to your specifications.

Your advantages at a glance

High-quality plastics

Manufacture of components made from PE, PA, POM, PEEK and PET (PETP).

Made to individual requirements

Production according to drawings or samples.

Small quantities

We start production at 1 piece – cost-efficient and fast.

State-of-the-art production facilities

Ultra-modern machines for diverse machining options.

Advantages of Murtfeldt format sets

- Quick adaptation to new formats at any time

- Easy assembly and disassembly

- Tool-free format change possible

- Easy to clean

- No accumulation of bacteria in hard-to-reach areas

- Project-oriented development work to provide complete plants and systems.

Advantages of the Murtfeldt plastics used

- Excellent slide properties result in the lowest possible dynamic pressure

- High wear resistance reduces the need for maintenance and new investments

- Compliance with EU and FDA food regulations on request

- Excellent surface quality due to machine production

- Stainless steel connecting elements to meet hygiene requirements

Have questions?

I’m happy to help you with any questions you have about our format sets.