Maintaining balance in extreme situations

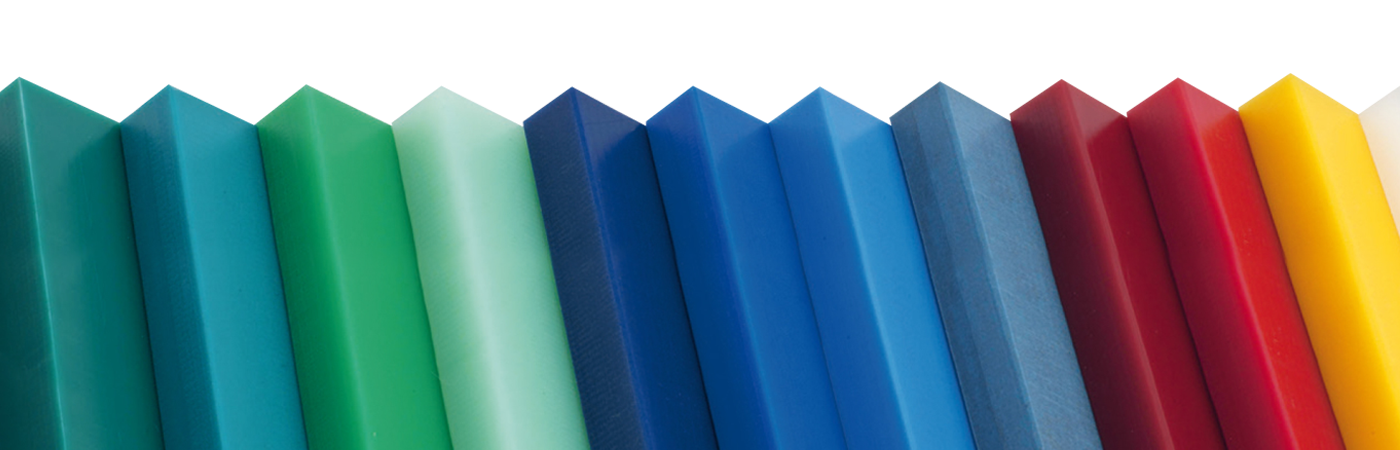

Low-friction, chemical and temperature resistant: Tailored to your requirements.

Plastic solutions for the chemical process industry

Resilient plastics for intensive processes

Product segments within the chemical process industry range from raw materials and industrial precursors to chemical end products. They all require increasingly intensive processes for efficient and flexible material conversion in chemical manufacturing. This reduces the use of raw materials, materials and energy, and thereby minimise both waste and costs.

We’re ready to take on your challenges and to support you with the design of tailored custom components. We base these designs on the most suitable plastic for your application, taken from our large selection of engineering and high-performance plastics.

Optimal use of plastics from Murtfeldt in the chemical industry

Alongside our large selection of engineering plastics, Murtfeldt Kunststoffe also offers selected high-performance plastics that are perfect for a number of specifications, including resistance to chemicals and high temperatures. Our Original Material "S"® range of plastics, and our high-performance plastic Murflor®, for example, excel with their high chemical resistance. Murpec®, on the other hand, is resistant to temperatures of up to 300 °C, which far exceeds many application requirements. This plastic also impresses with its resistance to numerous chemicals.

Where do you go from here? Use our Murtfeldt Plastics Guide. It's your first port of call for identifying the Murtfeldt plastics that are suitable for your application.

Need a custom design that makes optimal use of your selected plastic’s features and is tailored to your requirements? Our Application Technology team is ready to advise you and work with you on possible next steps.

Your advantages at a glance

- High impact resistance

- High resistance to chemicals

- Temperature resistance up to 300 °C

- Low wear rate

- High corrosion resistance

- Longer service life of plants

The chemical resistance of plastics

Chemical substances come into contact with numerous components in machines and plants when they are being conveyed. To guarantee optimum operational safety, components also need to withstand contact with aggressive chemicals. When it comes to selecting chemical-resistant plastics, we don’t just base our decisions on individual criteria; we look at a combination of various influencing factors as well. Practical application knowledge is often necessary here to be able to make an individual assessment.

Product examples

Possible uses

Murtfeldt products are used in near to all sectors of industry.

The right plastic

Our recommendations

The best plastics from Murtfeldt for use in your sector.

Have questions?

Our team is happy to help with any questions you have about our products and sector-specific solutions.

Application Technology

Phone

+49 (0)231 20609 1908

Application example

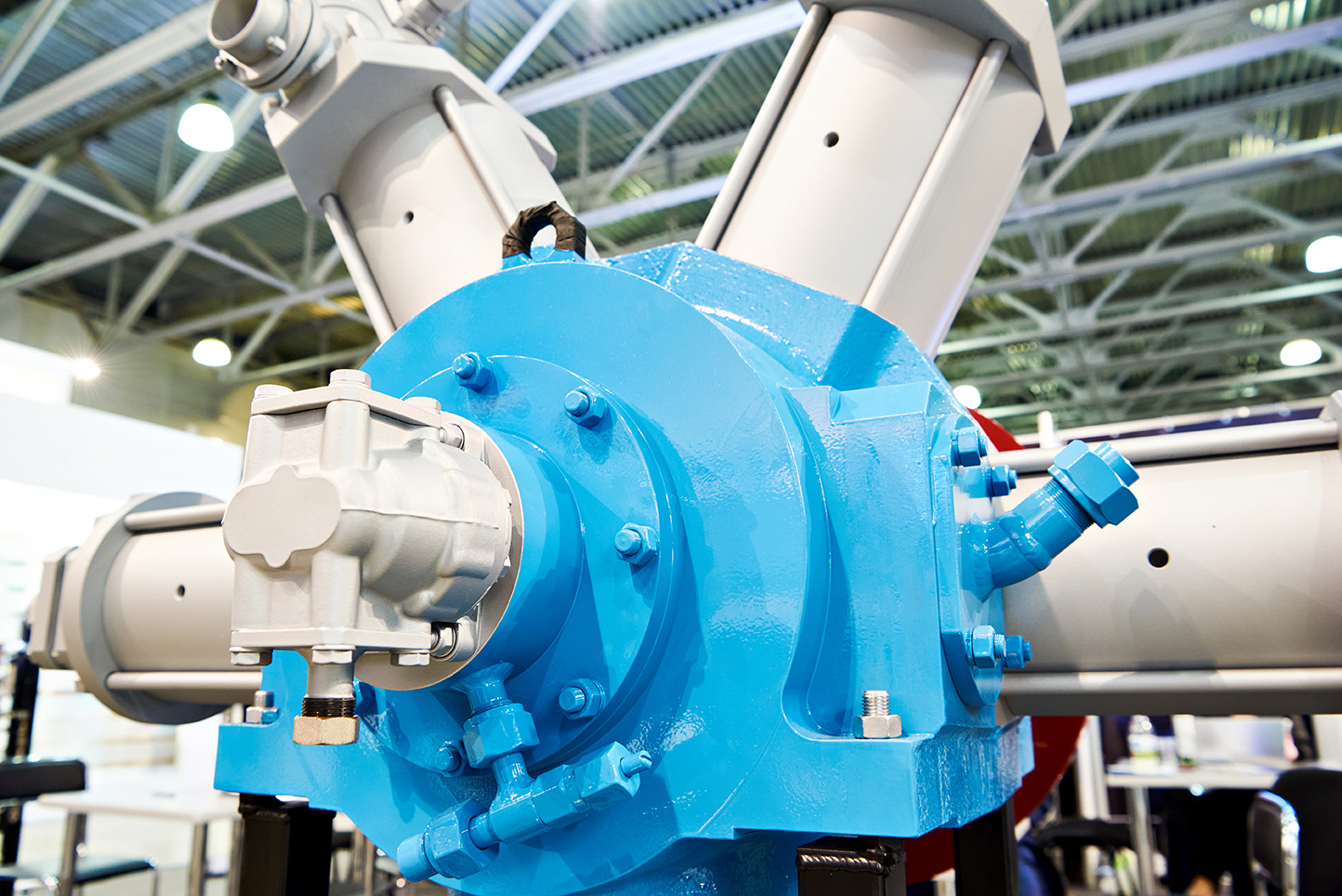

Valve plates for pumps and compressors

The efficiency and reliability of reciprocating compressors can be significantly improved by using valve plates made from Murpec®. In one particular case, valve plates made from Murpec® worked continuously for twelve months in a natural gas compressor, while some of the steel valve plates failed after just one month.

Valve plates are a key component in reciprocating compressors and have a direct influence on efficiency and reliability. If the plate is made from steel (which has a significantly shorter service life) and breaks, steel fragments can cause severe damage to the cylinder, piston and piston ring. The use of durable plates made from Murpec®, a modified PEEK, avoids such defects and offers end users in the oil and gas industry tangible added value by reducing both downtimes and the associated costs.

Valve plates made from Murpec® not only have a significantly longer service life, but also save energy when opening and closing. Less airflow is lost due to their superior wear resistance, surface adaptation, elasticity and, sealing performance. The polymer plates also generate less noise than steel. PEEK has proven to be the best material to replace stainless steel valve plates in the oil, gas and chemical industry.

Possible uses

Murtfeldt products in the chemical process industry

- At high temperatures

- In extreme environments with severe chemical impacts

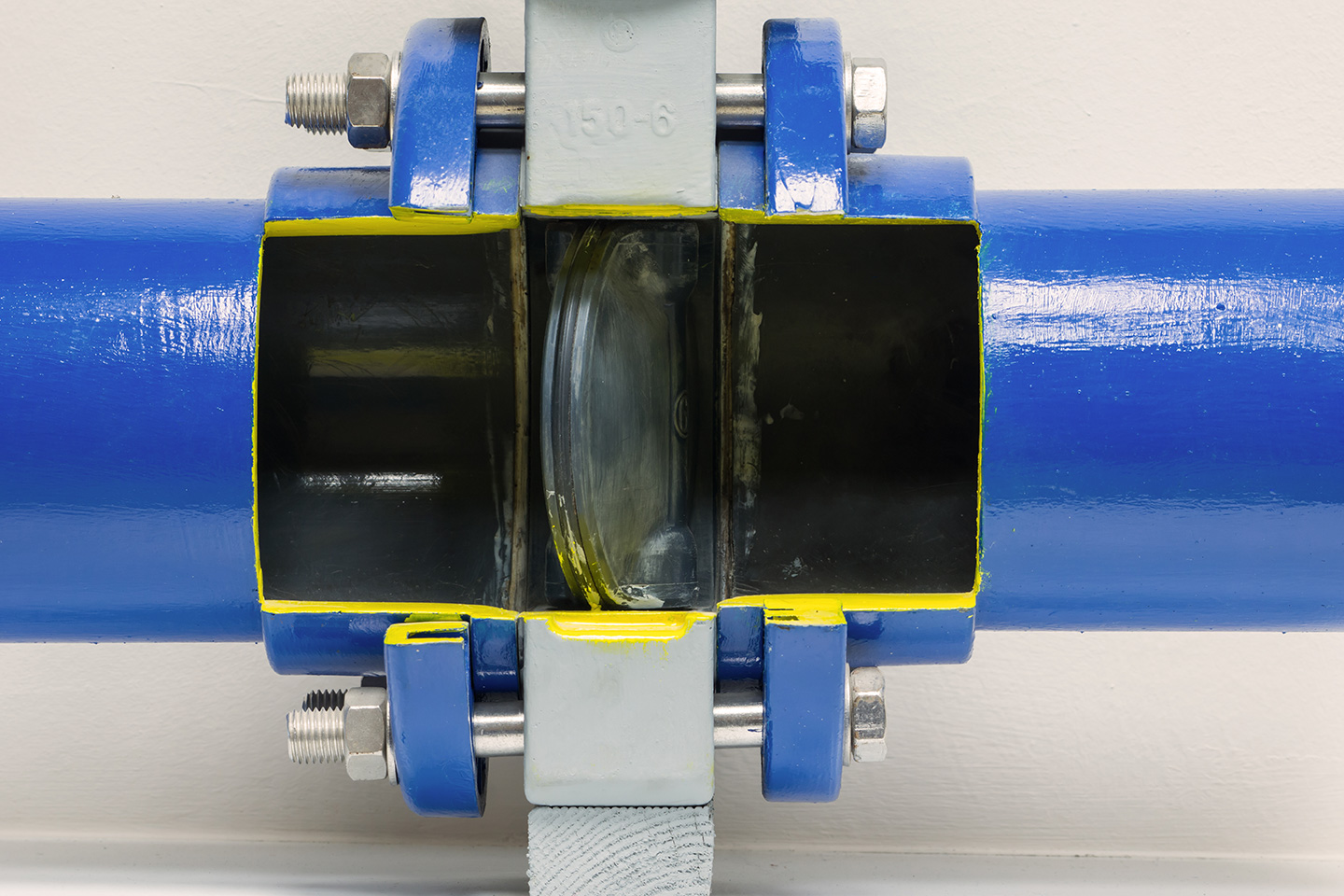

- In industrial pumps, compressors, valves and fittings

- In decanters and separators

Product examples

Custom made according to customer drawings on request

- Valve cones

- Sealing, packing, and spacer rings

- Valve plates in compressors and pumps

- Control discs in valves and fittings

- Labyrinth seals

- Bearing and guide elements

Our top recommendations

Murtfeldt plastics specifically suitable for the chemical process industry

PE plastics

Engineering plastics

High-performance plastics

We will gladly recommend additional plastics at your request.