Quality is our brand

Plastics for a highly specialized industry

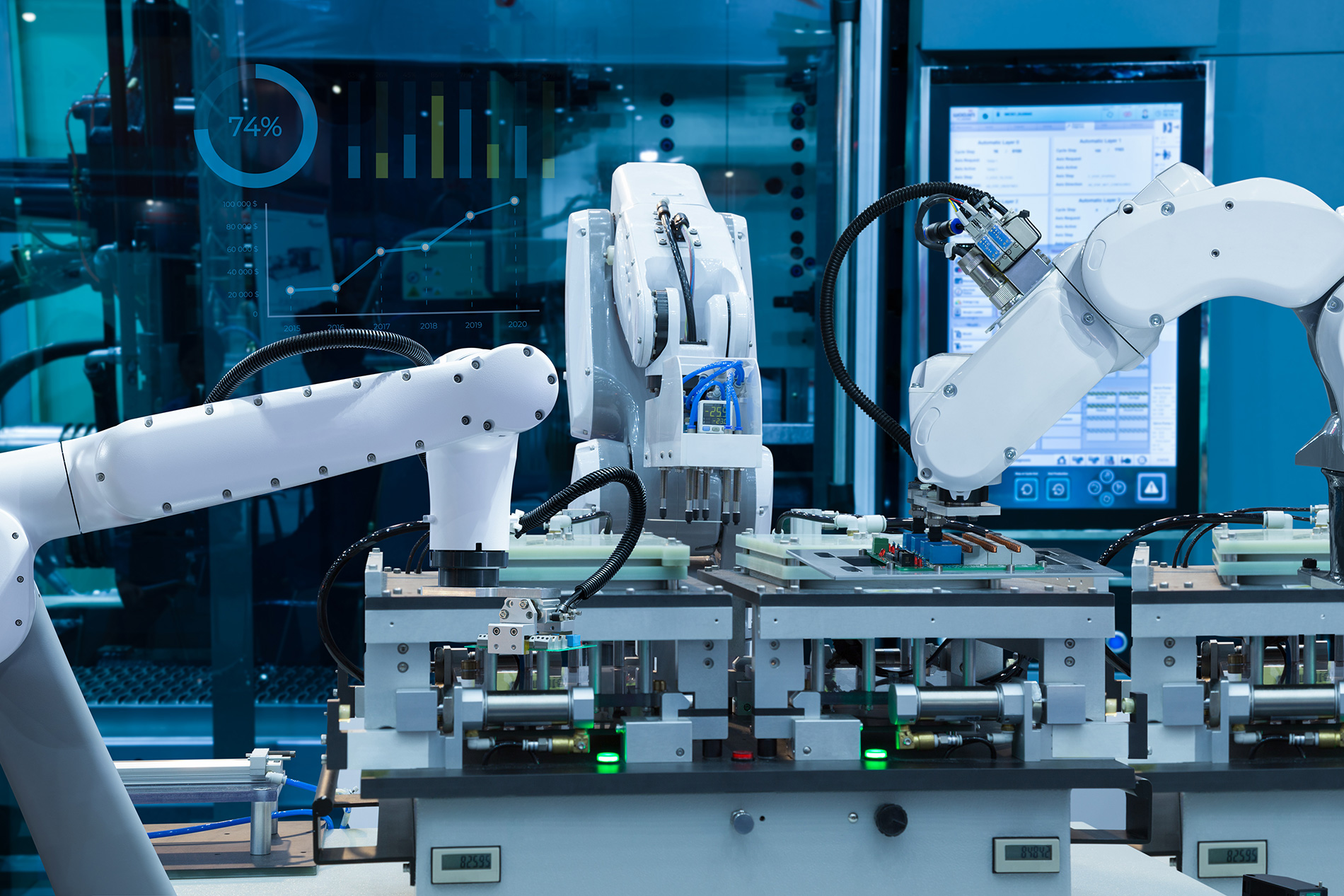

Plastic solutions for the electrical and semiconductor technology industry

High-quality surface finishes, conformity, and electrical dissipation guaranteed.

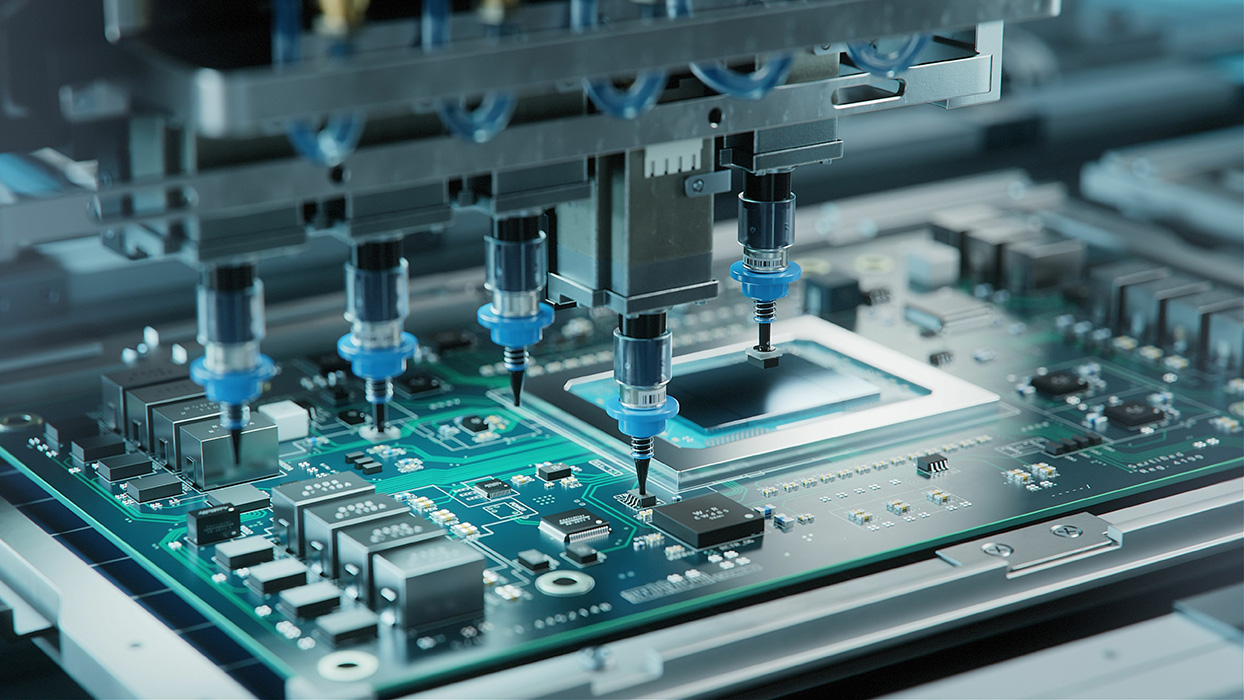

The electrical and semiconductor industryplaces extremely high demands on design engineers and their product developments made from engineering and high-performance plastics. It does so as every production step is subject to considerable environmental requirements.

Aggressive chemicals and solvents as well as plasma cleaning during the production process set the bar very high for materials and mean that design, machining tolerances, outgassing and contamination specifications are subject to very strict requirements. Insulating parts for electric and electronic technology require materials with high surface and contact resistance, as well as electric strength. In high-frequency technology, on the other hand, dielectric properties are the primary requirement. The outgassing of materials used in this environment also plays an important role. Complying with the exacting requirements set for the purity of plastics in terms of outgassing and ionic impurities reduces risk of contamination and thereby the reject rates of components.

In short: the protection of product components is given a very high priority.

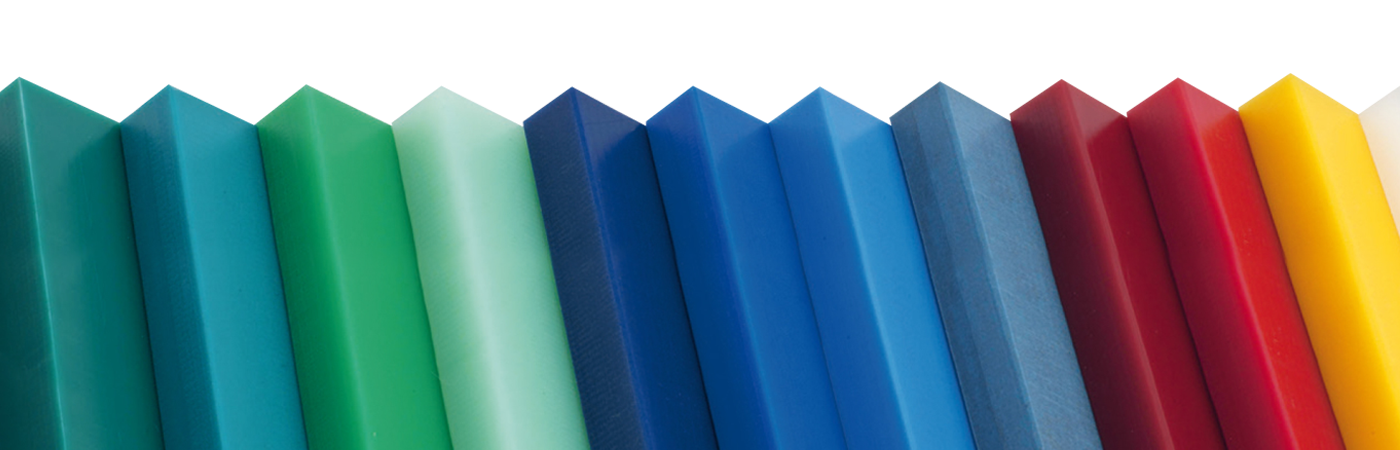

The demand for plastics with specific properties or property combinations is therefore high in the electrical and semiconductor industry. Metals often cannot keep up with thermoplastics when it comes to corrosion and chemical resistance, and ceramics and glass are too heavy to be used. Plus, our selection of plastics offers the right material for your specific application, whether you need it to be insulating, electrically dissipative or resistant to chemicals.

Plastics for highly sensitive requirements

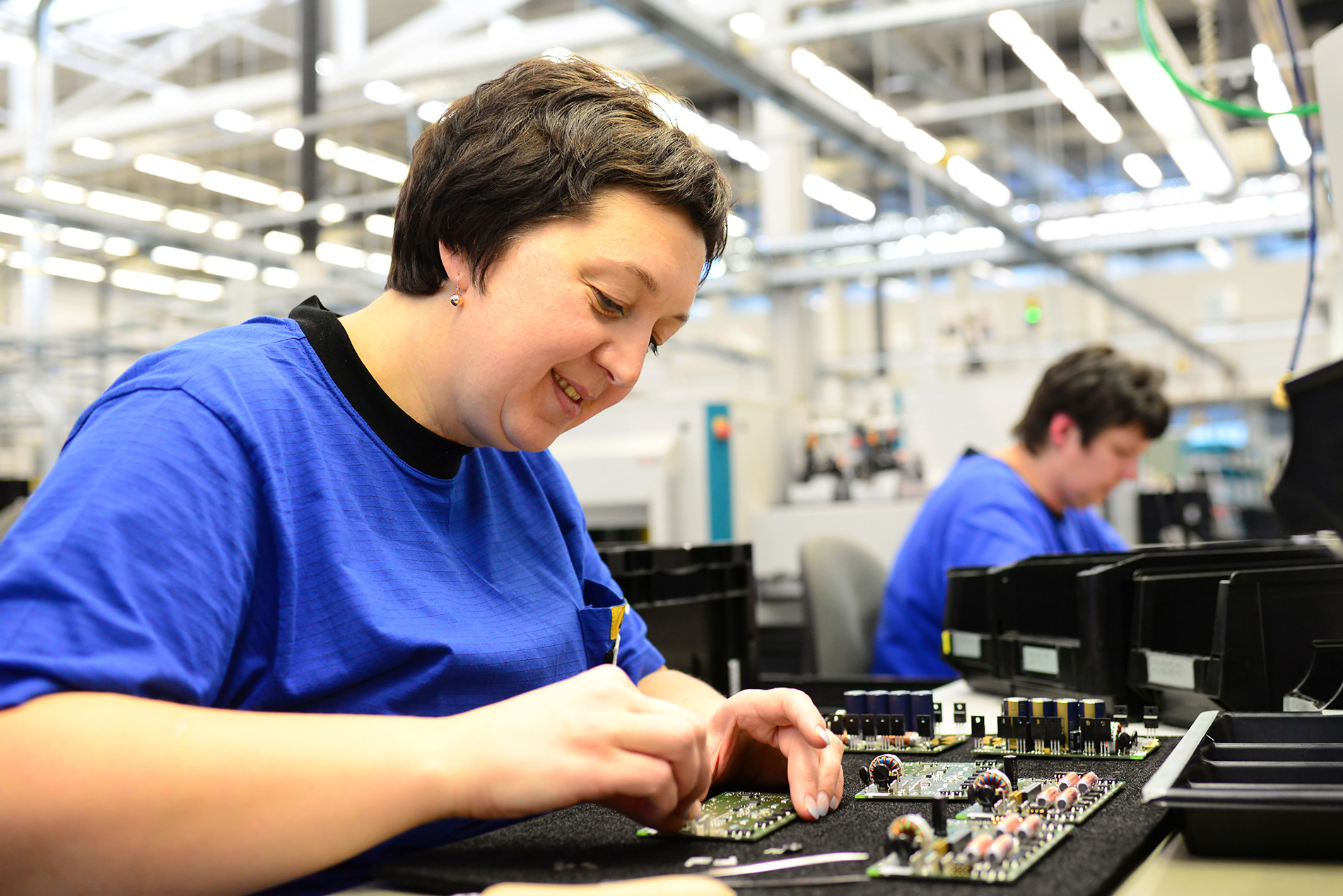

Murtfeldt offers modified plastics that deliver required properties including electrical conductivity, antistatic properties, and static dissipation. These properties are especially important in semiconductor applications such as back-end test sockets. Our Original Material “S” plus+® white ESD engineering plastic is perfect for this, offering surface dissipation in the resistance range of ≥ 1x104 Ω to 1x1011 Ω . Opting for Murtfeldt’s dissipative plastics for work surfaces, means that ESD-sensitive (ESDS) products can be processed on them without any problems arising.

Your advantages at a glance

- A choice of insulating and static-dissipative plastics

- High chemical resistance

- No corrosion

- Minimal outgassing

- Superior protection for your products, resulting in fewer rejects

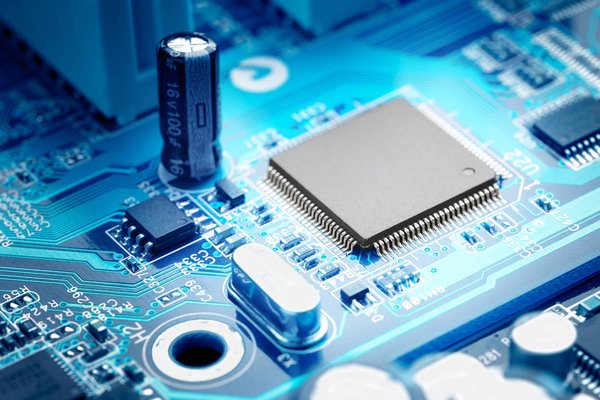

Protecting electronic components – an example

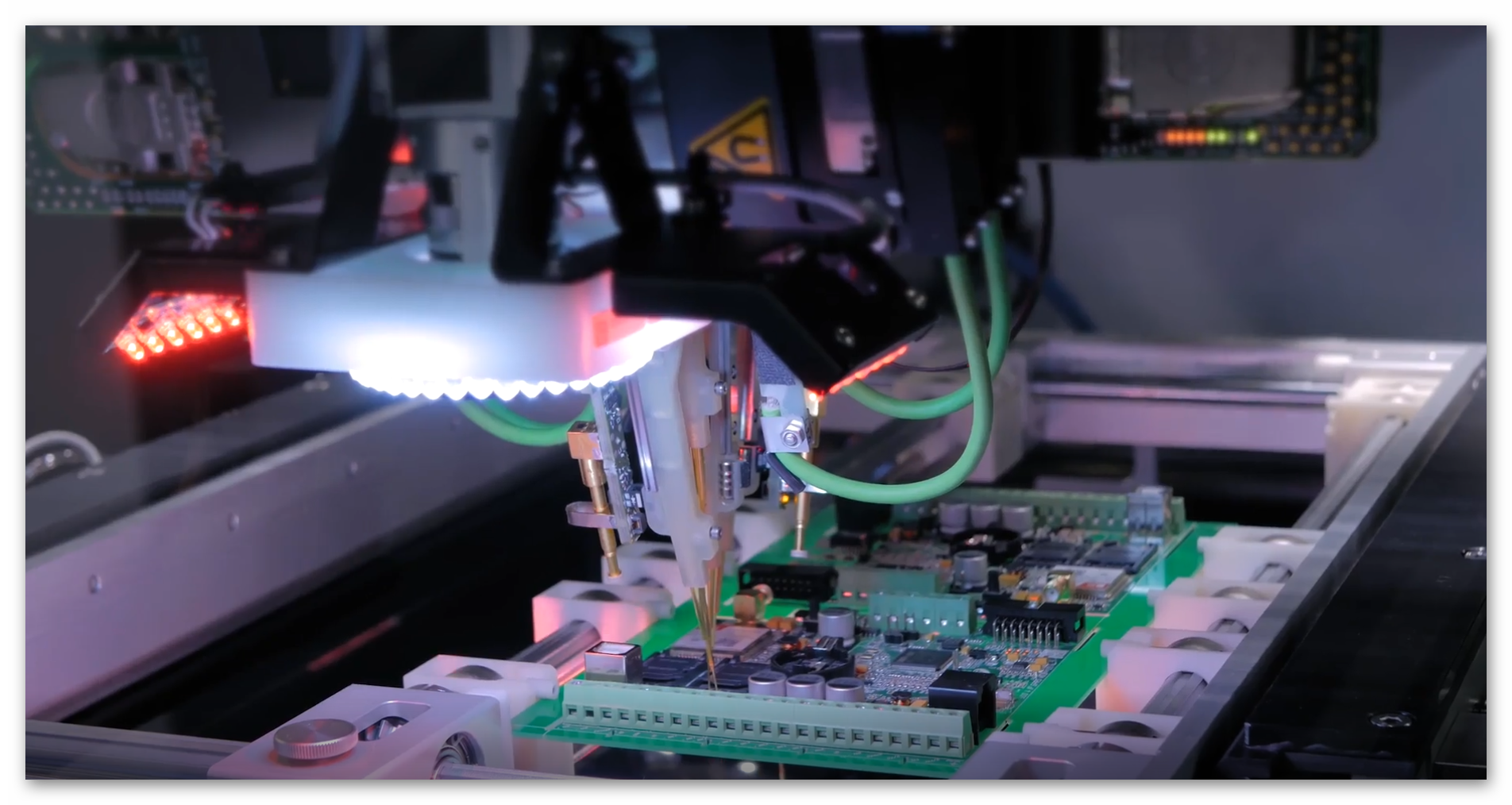

Effective countermeasures prevent sudden discharges from causing costly consequences for electronic components and assemblies. Our dissipative Murtfeldt plastics help to make working environments safe by averting electrical charges or preventing rapid discharges through slow dissipation. A standardised resistance measurement is needed to establish whether the plastic used is suitable. This requires the use of suitable measuring devices with measuring probes, which measure across the surface. Test probe tips can lead to incorrect results due to point-by-point measurements. The Murtfeldt team is happy to take these measurements for you.

Product examples

Possible uses

Murtfeldt products are used in near to all sectors of industry.

The right plastic

Our recommendations

The best plastics from Murtfeldt for use in your sector.

Have questions?

Our team is happy to help with any questions you have about our products and sector-specific solutions.

Application Technology

Phone

+49 (0)231 20609 1908

Possible uses

Murtfeldt products in the electrical and semiconductor technology industry

- Approved for areas requiring ESD protection according to the EPA (standards 61340-5-1 and DIN EN 61340-5-1)

- Suitable for devices and machines that are subject to Directive 94/9/EC (ATEX 95)

- Clean room technology and laboratory environments

- Chip production

- Suitable for low-contamination wafer production with high quality requirements

- Work processes with elevated temperatures

- For contact with highly abrasive solutions

- Potentially explosive areas In environments with various, highly aggressive chemicals

- In the manufacture of sensitive electronic components that require slow dissipation

- Plasma cleaning

Product examples

Custom made according to customer drawings on request

- Electrically dissipative mounting plates

- Plug-in couplings and mounts

- Rail connectors

- Cable holders and cable clamps

- Circuit breakers

- Etching and CVD chamber applications

- Wafer handling applications

- Structural applications for wet processes

- Wet process components

- Grippers for wafers and solar cells