Lightweight. Slide-optimised. Wear-resistant

Engineering plastics as an alternative to steel.

Plastic solutions for machine construction and drive technology

Components for industrial machines – made from our reliable and innovative engineering plastics.

As a company specializing in machine construction or drive technology, you manufacture systems for entire sectors of industry, many of which are tailor-made to meet the needs of your customers. Failure of these systems would inevitably lead to stoppages in production and significant costs. And this isn’t the only challenge with significant potential for stress. Increasing globalisation has amplified what is already a highly competitive environment, even though the “made in Germany” label continues to enjoy unwavering recognition worldwide.

Machine constructors and manufacturers in drive technology are often faced with similar problems. Manufacturing operations for all kinds of products have to cope with processes where materials wear out quickly due to abrasion, aggressive chemical substances, high production speeds, and extreme temperatures.

Such challenges are often addressed by using steel and metal alloys. They are able to guarantee a component’s high mechanical strength and precision. But they also present a number of disadvantages. Their heavy weight, corrosion, and need for lubrication are just a few of the factors that speak against the use of metals. Opting for alloys has its own disadvantages in terms of high prices.

This explains why engineering plastics have been constantly gaining ground in the fields of machine construction and plant engineering for years. The use of plastics to replace metals is becoming more and more common, as their advantages are undeniable. Both engineering and high-performance plastics are usually excellent alternatives for the kinds of stresses mentioned above. And they offer more opportunities for improvement and progress. Given this backdrop, it is understandable why design engineers, machine constructors, and maintenance technicians often see plastics as a convenient solution for mechanical components and various other applications. We are happy to advise you further on plastics, or components made from high-quality Murtfeldt plastics, with the right properties for your project.

Low coefficient of sliding friction,

excellent hold –

an example

By using slide bearings made from Murtfeldt plastics in the construction of pipe bridges, dangerous movement caused by changes to the length of the pipeline can be avoided. This potential movement is down to the transition between static and sliding friction. Using our plastics with low coefficients of sliding friction instead of metal solutions helps to solve this problem.

Product examples

Possible uses

Murtfeldt products are used in near to all sectors of industry.

The right plastic

Our recommendations

The best plastics from Murtfeldt for use in your sector.

Have questions?

Our team is happy to help with any questions you have about our products and sector-specific solutions.

Application Technology

Phone

+49 (0)231 20609 1908

Application example

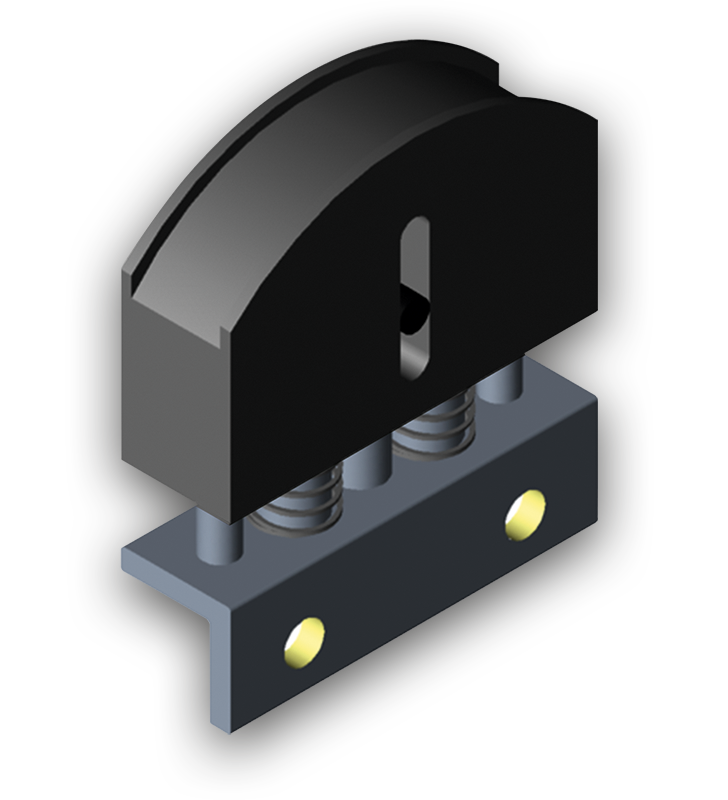

Mini-tensioner used on bikes for people with physical disabilities

Draisin bikes are specially designed models for one person, or for two to use at the same time. Some come with double chain wheels and two chains, others with a single very long chain. The original tensioning device, which was designed in-house, had to be readjusted frequently to achieve optimal tension. Draisin sought a third-party solution that could meet clear specifications: the chain tension needed to be optimised to reduce wear. The frequently required re-tensioning of the chains also needed be eliminated. We developed a special version of our mini-tensioner with a U profile and strong tension force. The tensioner’s colour was also adapted for its new environment. We scored points here by making the mini-tensioner easy to handle, keeping its height to a minimum, and providing expert advice with alternative suggestions.

Possible uses

In the field of machine construction and drive technology, Murtfeldt products are used in a variety of areas, including:

- Paper manufacturing plants

- Auto paint shops

- Milking technology

- Storage technology

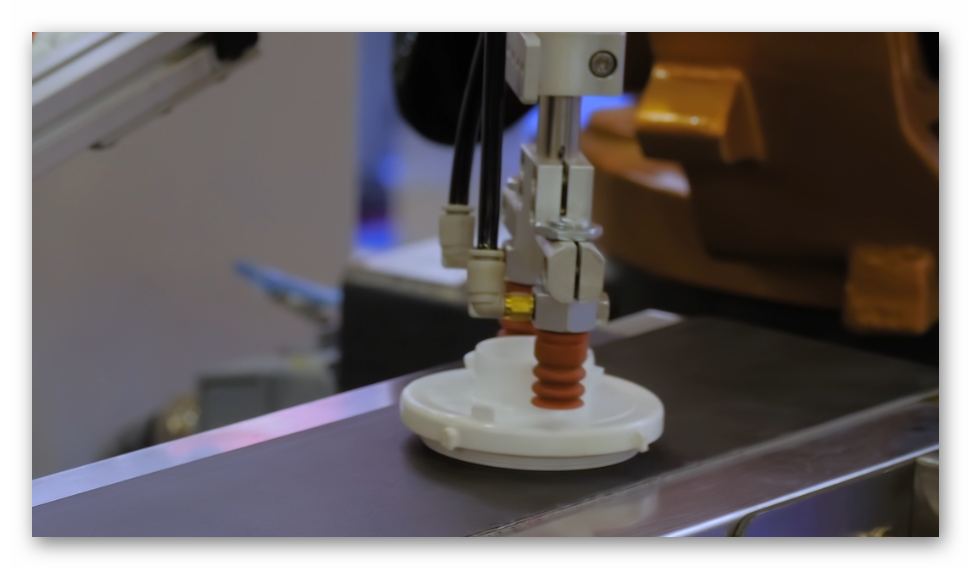

- Industrial robots

- Textile and construction machinery

- Packaging plants

- Wind power and solar energy environments

- Agricultural machinery

Product examples

Custom made according to customer drawings on request

- Drive elements

- Transport and conveying screws

- Chain guides

- Machine parts with tight tolerances

- Guide rails

- Slide elements

- Parts subject to shock and impact stresses