Hygiene and speed for the beverage and bottling industry

Engineering plastics increase efficiency and image.

Plastic solutions for the beverage and filling industry

Components made from food-grade plastics for safe, fast and smooth beverage filling

As well as exceptional ingredients and technical expertise, producing a top-quality and great-tasting beverage calls for innovative equipment, which is substantially invested in on a regular basis. In this context, you, as a company in the beverage industry, are faced with ever increasing demands.

We know that there are stringent legal requirements regarding product quality and food safety in the food, beverage and filling industry. Hygiene is paramount and technical improvements are always sought after. Murtfeldt Kunststoffe is here to support you with durable, chemically resistant and food safe products. These are manufactured by us using machining processes. At your request, they can also be designed by our experienced application engineers to meet your specific needs. We are committed to producing high-quality and safe products for your company. Regular audits and certifications help us strive for perfect results and a low reject rate.

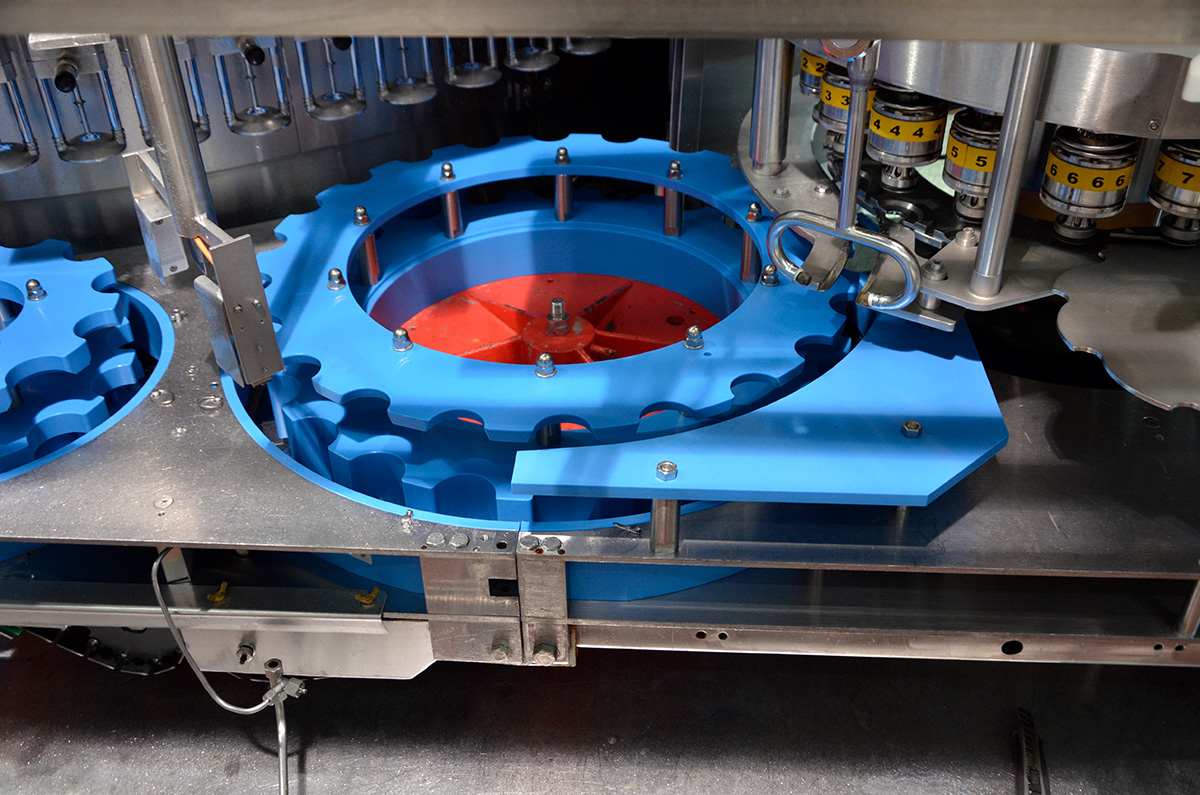

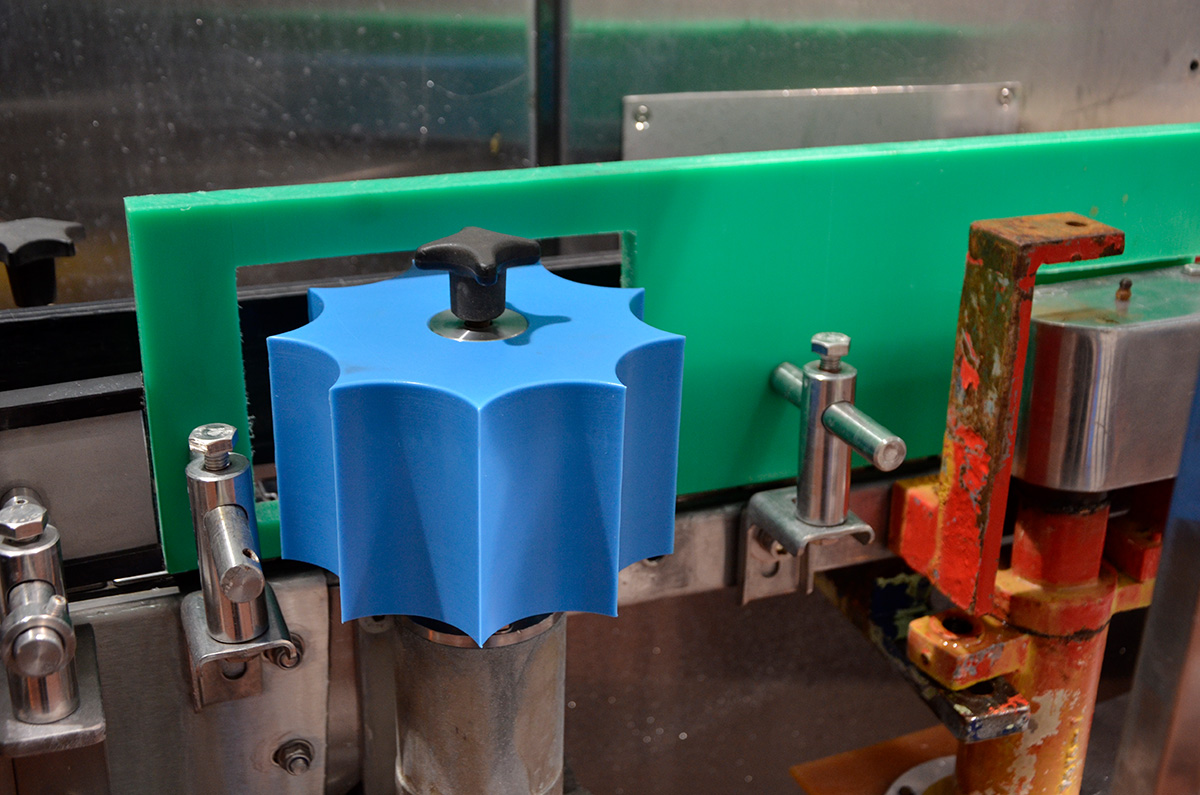

Plastic bottle gripper jaws as a hygienically sound solution

Rinsers, for example, are used in the sterilisation process for rinsing out glass bottles and sterilising without leaving behind any particles. Bottle gripper jaws in the rinsers grip the bottles to be cleaned and transport them through the rinser. These gripper jaws are often still made from rubber, and can’t compete with gripper jaws made from Murtfeldt plastics in terms of hygiene. We are happy to advise you on changing your gripper jaws over to a suitable plastic from our product selection.

Our plastics comply with EU and FDA food safety regulations, and can also be made metal-detectable on request. Special laboratory formulations ensure surfaces are protected against germs, bacteria and viruses. Plus, our products are characterised by their high abrasion and wear resistance, which enables them to withstand long machine running times and the use of intensive cleaning agents.

Plastics that meet EU and FDA food safety regulations

Through our plastics solutions, we support you as a food manufacturer, or manufacturer of machinery and systems for the food industry, with machine components that ensure the highest levels of hygiene and food safety. In addition to plastics that comply with EU and FDA food regulations, we also offer a wide range of detectable plastics to ensure the safety of your processes. Plus, our products are characterised by their high abrasion and wear resistance, which enables them to withstand long machine running times and the use of intensive cleaning agents. Continuous migration tests guarantee compliance with legal requirements for what are known as ‘food contact materials’, which also include Murtfeldt products such as drive and conveying screws, product turners, dough scrapers, and more.

Your advantages at a glance

- Plastics approved for use in the food industry

- Suitable for direct contact with foodstuffs

- Visually identifiable and metal-detectable plastics

- Excellent hygiene and cleaning properties (chemical resistance)

- Wide variety of materials in the food safe segment - the right solution for every application

- Long service life

- Low risk of failure

- Long machine runtimes possible

- Gentle handling of your products

Detect foreign objects, protect your brand – an example

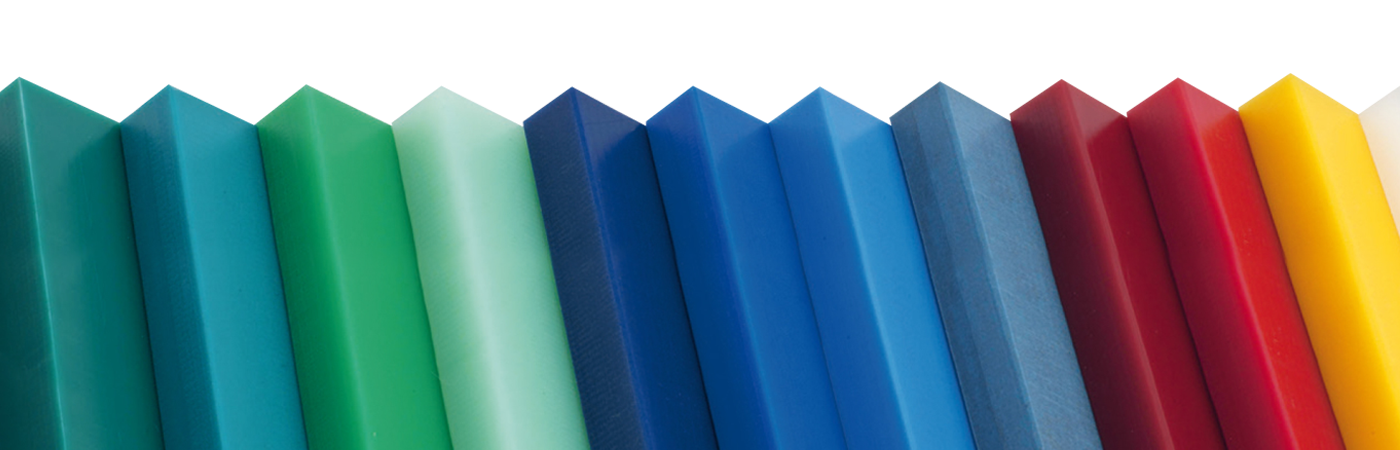

Despite the greatest care being taken, plastic foreign bodies can inadvertently get into food during the production process. Our extensive choice of coloured Murtfeldt plastics can help you in identifying and removing any particles that do occur, either visually or via detector. This enables you to avoid product recalls, and possible damage to your brand image, and also to maintain your high quality assurance standards.

Product examples

Possible uses

Murtfeldt products are used in near to all sectors of industry.

The right plastic

Our recommendations

The best plastics from Murtfeldt for use in your sector.

Have questions?

Our team is happy to help with any questions you have about our products and sector-specific solutions.

Application Technology

Phone

+49 (0)231 20609 1908

Application example

Rinser grippers in the (sparkling) wine filling sector

To improve hygiene during sterilisation, we have replaced rubber gripper jaws in the rinsers of many beverage filling plants with gripper jaws made from high-quality engineering plastics. Our Original Material “S”® plus+ AB, for instance, contains special substances that prevent the growth of microbes while not being harmful to humans or the environment. This prevents the development of unpleasant odours and the formation of biofilm. In addition, ”S”® plus+ AB has demonstrated high abrasion resistance along with strong resistance to chemicals in many applications without showing any moisture absorption.

A changeover quickly yields positive results. The time and effort spent on cleaning are usually significantly reduced, tighter tolerances can be optimally maintained due to better centring, and the entire operation is generally trouble-free. Two further advantages of plastic gripper jaws: hygiene is noticeably improved and plants are able to run with greater precision.

Possible uses

Murtfeldt products in the food industry

- Rinsers

- Fillers

- Corkers

- Cappers

- Capsule machines and labellers for breweries and (sparkling) wine producers

Product examples

Custom made according to customer drawings on request

- Drive and conveying screws

- Product turners

- Format sets

- Grippers for rinsers

- Pucks Inlet and outlet screws

- Core components

- Stoppers

- Cappers

- Inlet or outlet carousels

- Outer guides