Lightweight and energy saving

Make a contribution to environmental protection with Murtfeldt plastics.

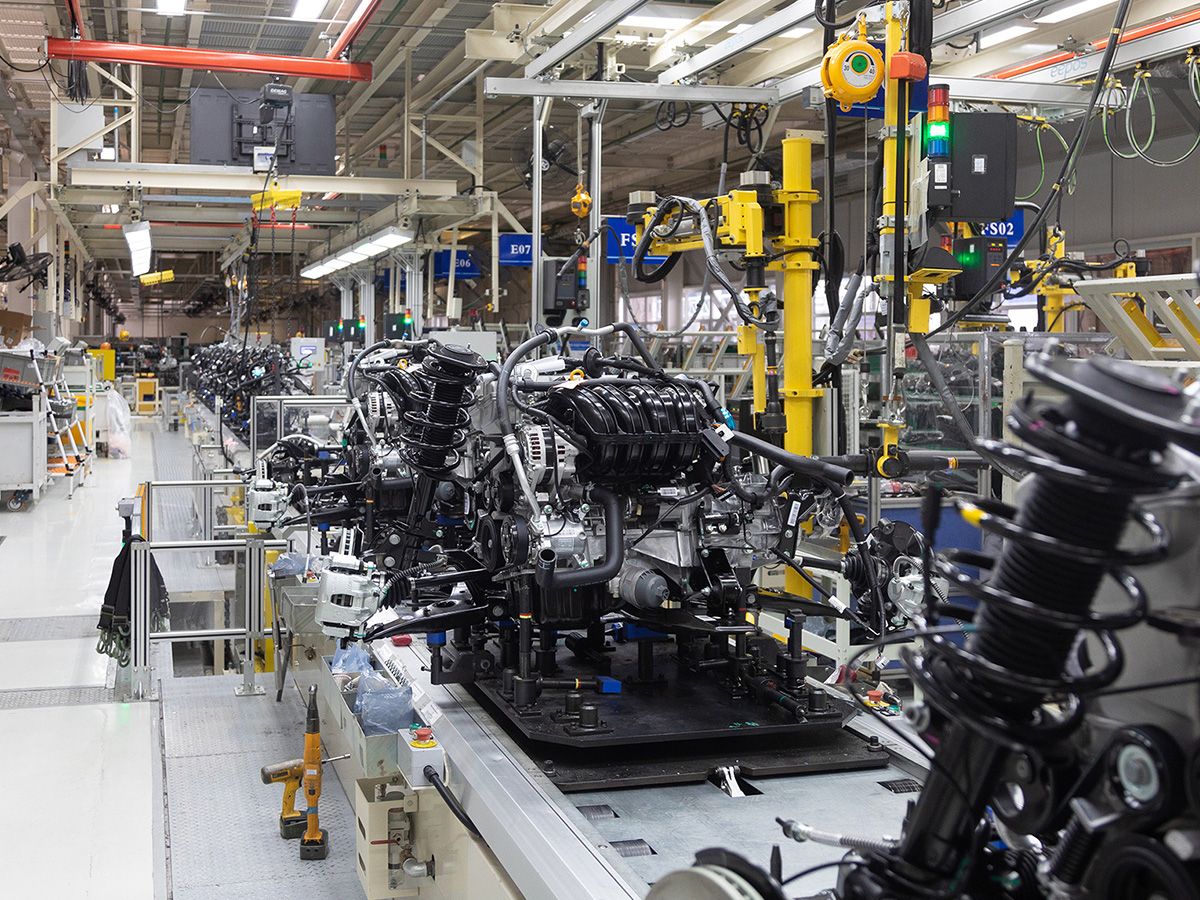

Murtfeldt solutions for the automotive industry

Plastic solutions across the supply chain

With its shift away from internal combustion engines towards e-mobility, the transition taking place in the automotive industry is enormous . But plant efficiency and energy conservation continue to play important roles within this new approach to mobility.

Murtfeldt’s engineering plastics have grown in relevance in this area over the last decades. Thanks to their modifiable properties, sensitive surfaces, and minimal weight, they have become indispensable in the automotive industry. Our specifically developed plastics feature impressive slide properties and wear resistance thanks to their consistently low coefficient of sliding friction without the need for silicone. Optimised slide properties are also achieved with sliding partners made from POM or PP, which increase the dynamic load-bearing capacity of conveyor systems. In addition, maintenance is also less intensive thanks to reduced abrasion.

Your advantages at a glance

- Engineering services (structural design, solid-state simulations, reverse engineering, 3D scans, material design and calculations)

- Long service life

- Less maintenance time

- Shorter downtimes

- Low risk of failure

- Long machine runtimes possible

- Gentle handling of products

- Silicone-free plastics

- Next to no water absorption

- Break and shatter-proof

- High dimensional stability and accuracy

- High resistance to chemicals

- High compressive strength

- Excellent price/performance ratio

- Compliance with LABS, ROHS, REACH and ESD

New technologies need new solutions – an example

The transition towards e-mobility also requires changes within plant technology and design. Heavier components, such battery stacks, which have to be handled now, pose new challenges for intralogistics. Plastics used in conveying applications also need to withstand increased loads and surface pressures. We work with you to design materials for your plant retrofit. The ever-increasing number of new electronic components in vehicles also requires a completely new approach. ESD protection, for example, plays a crucial part here. Modified Murtfeldt plastics fulfil key functions in this regard as well.

Product examples

Possible uses

Murtfeldt products are used in near to all sectors of industry.

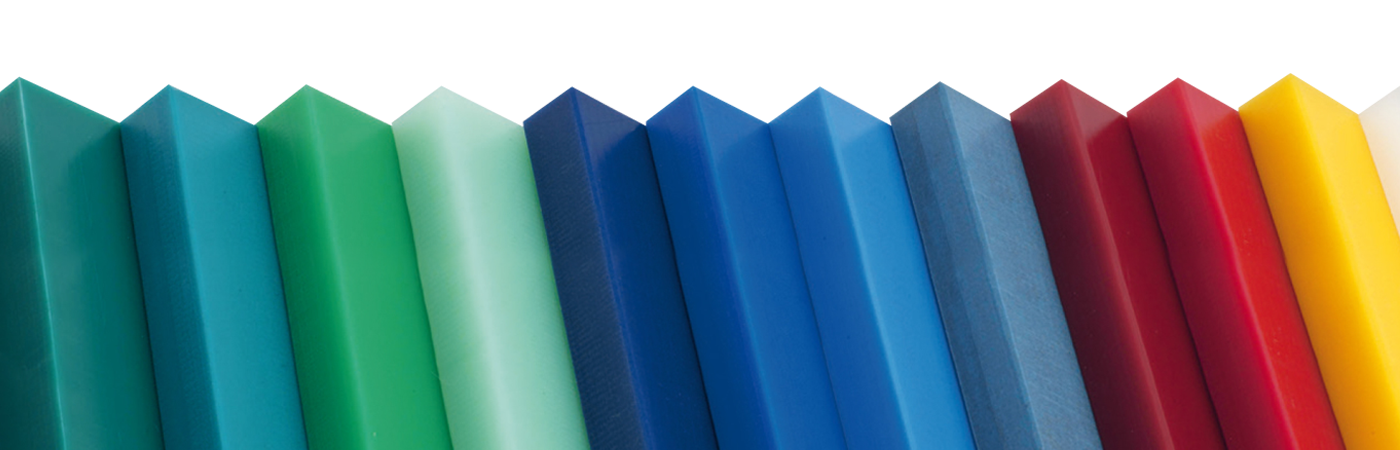

The right plastic

Our recommendations

The best plastics from Murtfeldt for use in your sector.

Have questions?

Our team is happy to help with any questions you have about our products and sector-specific solutions.

Application Technology

Phone

+49 (0)231 20609 1908

Possible uses

Murtfeldt products in the automotive industry

- Custom plastic parts for all plant components

- Parts and components for Tier 2 and Tier 3 suppliers

- Systems and modules for Tier 1 suppliers

- For maintenance of OEMs

- Replacement parts, retrofits and conversion of plants and machines

Product examples

Made to order according to customer drawings

- Chain guides and slide bars

- Plastic components for load carriers, workpiece carriers and transport racks

- Component holders

- Spacers

- Bumpers and protective guards

- Assembly aids and templates

- Jigs & fixtures

- Gauges

- Sliding bases for modular link belts