For fast-paced and precise production

Lighter and more flexible thanks to weight-reduced construction plastics.

Plastic solutions for automation

Lightweight and individually adapted structural components made from plastic facilitate dynamic further development.

Theuse of plastics in the automation industry is a key trend that has gathered momentum in recent years. The advantages of plastics in automation technology are manifold, ranging from their lighter weight and lower costs to increased flexibility and easy assembly options.

Plastics for automation

Another key application area for Murtfeldt plastics in the automation industry is the manufacture of components that can be electrically insulative as well as electrically dissipative (ESD protection). These also offer excellent chemical resistance, which makes them ideal for use in automation. Our plastic components are also lighter and more flexible than metal solutions, making assembly and installation easier and operation more efficient.

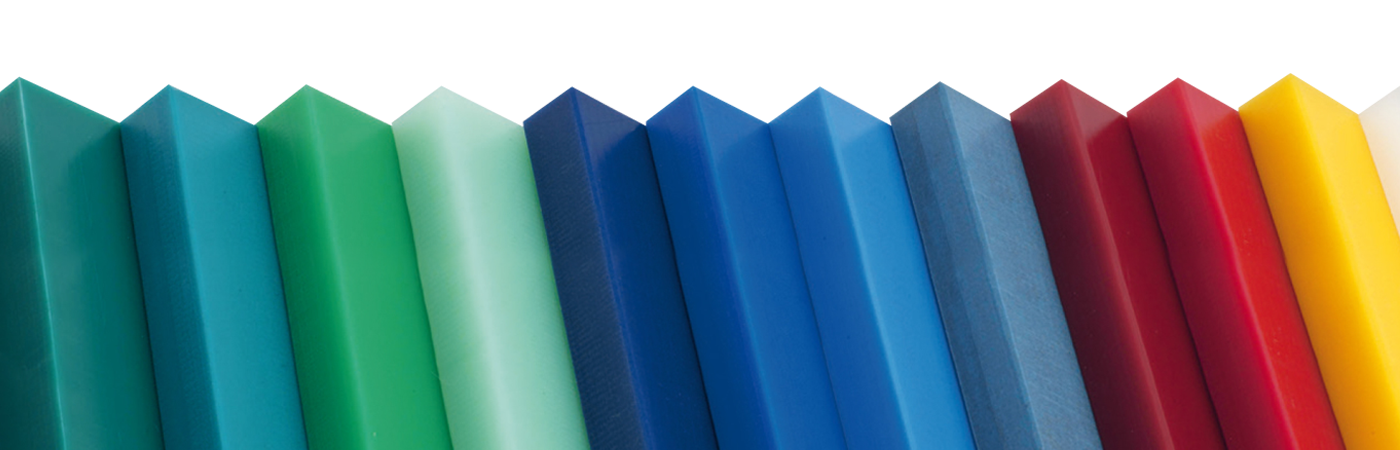

In addition, our engineering plastics can be used as lubricants or sliding partners to reduce friction and wear within automation technology. The plastics from our Original Material “S”®range are known for their excellent slide properties, as well as their chemical and wear resistance.

Overall, there are a number of advantages to using plastics in the automation industry, which result in greater efficiency, easier assembly and installation processes, as well as lower costs and greater durability.

Your advantages at a glance

- Space-saving integration into automation plants

- Extended maintenance intervals thanks to minimal wear

- Individual design to suit your application – optimum use of materials with application-specific designs and topology-optimised construction

- Wide range of Murtfeldt plastics for precision-fit machine elements that support exact positioning and movements

- Range of different manufacturing processes enables optimisation of positioning and handling applications.

The lightness of plastics –

an example

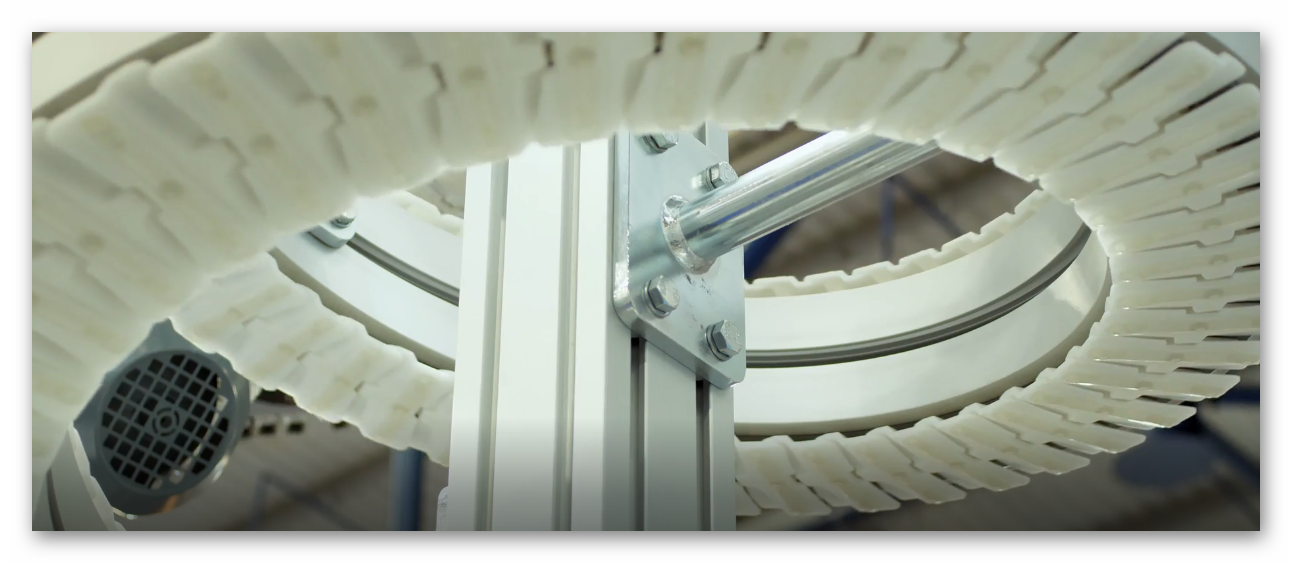

Most plastics have a density of between 800 and 2,300 kg/m³. So they are considerably lighter than metals or ceramic materials. This means our Murtfeldt plastics can now be used to realise applications and create components that metal materials would not have been able to produce. An example here is their use for machines where items have to be handled at high speed as centrifugal forces limit performance in this field. Only the use of plastic (seven to eight times lighter than steel on average), makes significantly higher speeds possible on account of its lighter weight.

Product examples

Possible uses

Murtfeldt products are used in near to all sectors of industry.

The right plastic

Our recommendations

The best plastics from Murtfeldt for use in your sector.

Have questions?

Our team is happy to help with any questions you have about our products and sector-specific solutions.

Application Technology

Phone

+49 (0)231 20609 1908

Possible uses

Murtfeldt products in the automation industry

- Production lines

- Pick & place applications

- Manufacture of e-vehicles

- Conveyor systems

- Demanding environments

- Low-friction and reliable movement of guide systems

Product examples

Custom made according to customer drawings on request

- Linear guides and guide rails

- Workpiece carriers: ensure precise alignment and positioning for pick & place applications.

- Pucks: a special kind of workpiece carrier. Precise and product-friendly containers that ensure safe transportation and handling of sensitive products throughout the entire plant.

- Handling components: grippers and feeding components

- Jigs and fixtures: jigs and positioning aids for smooth automation

- Lightweight components for more efficient and faster production flows