Tension in dynamic applications

The new Spann-Boy® TS-EP from Murtfeldt

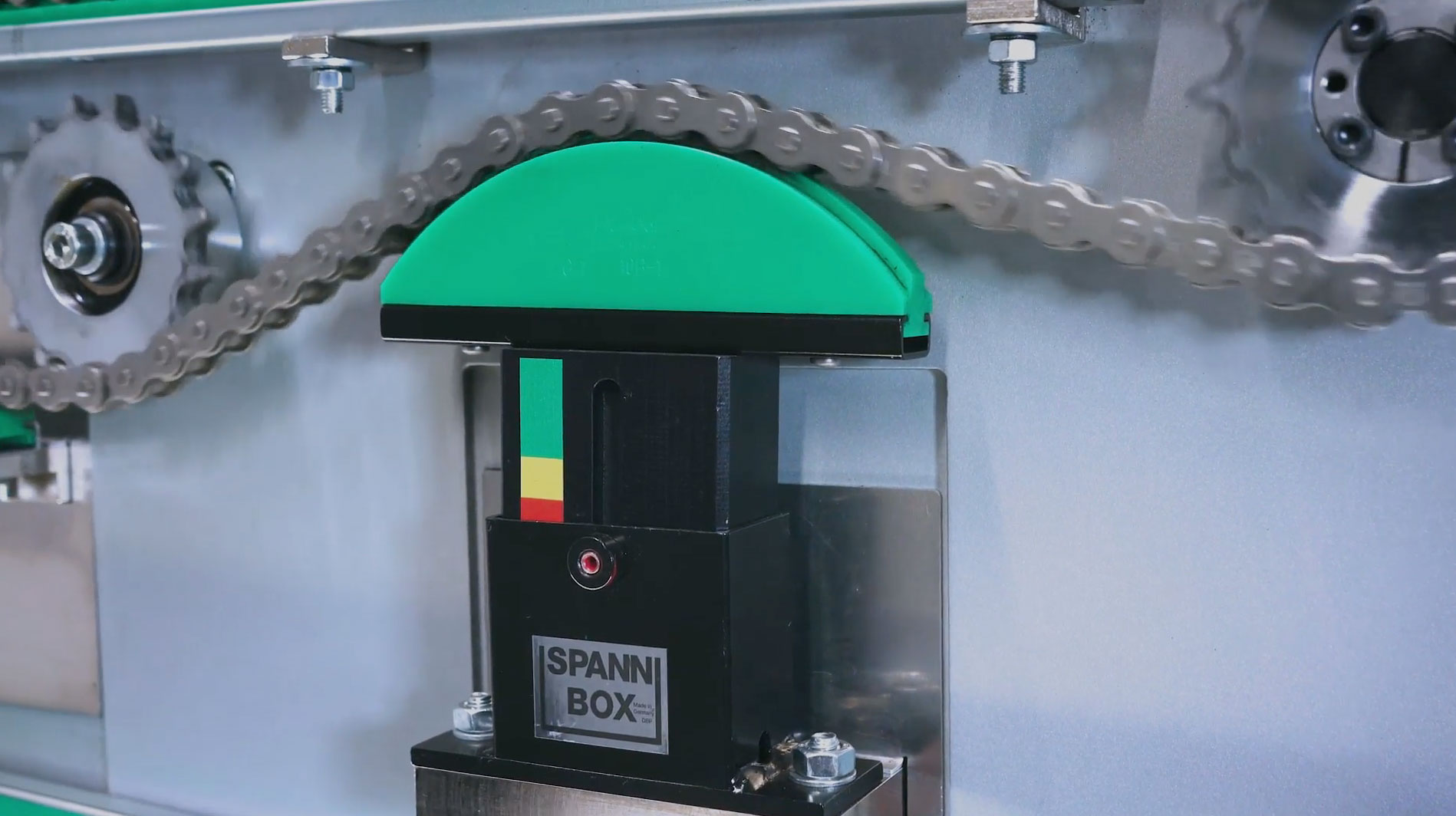

Spann-Boy® TS-EP

The new Spann-Boy® TS-EP for dynamic applications

What initially started out as a special solution by Murtfeldt for specific customer requirements is now establishing itself as something of a new benchmark product as demand continues to grow: the new Spann-Boy® TS-EP, an elliptical, 180° pivot-mounted chain slide profile made from Murtfeldt’s Original Material "S"®.

If you are looking for greater flexibility in the installation and adjustment of tensioning systems, then the new Spann-Boy® TS-EP is exactly the product you need. Find out more about its advantages, of which dynamic adjustment in response to increasing chain elongation and automatic adaptation to chain movement are just two examples.

Pivot-mounted chain slide profile

Versatile use

Interested in our Spann-Boy® TS-EP?

Features

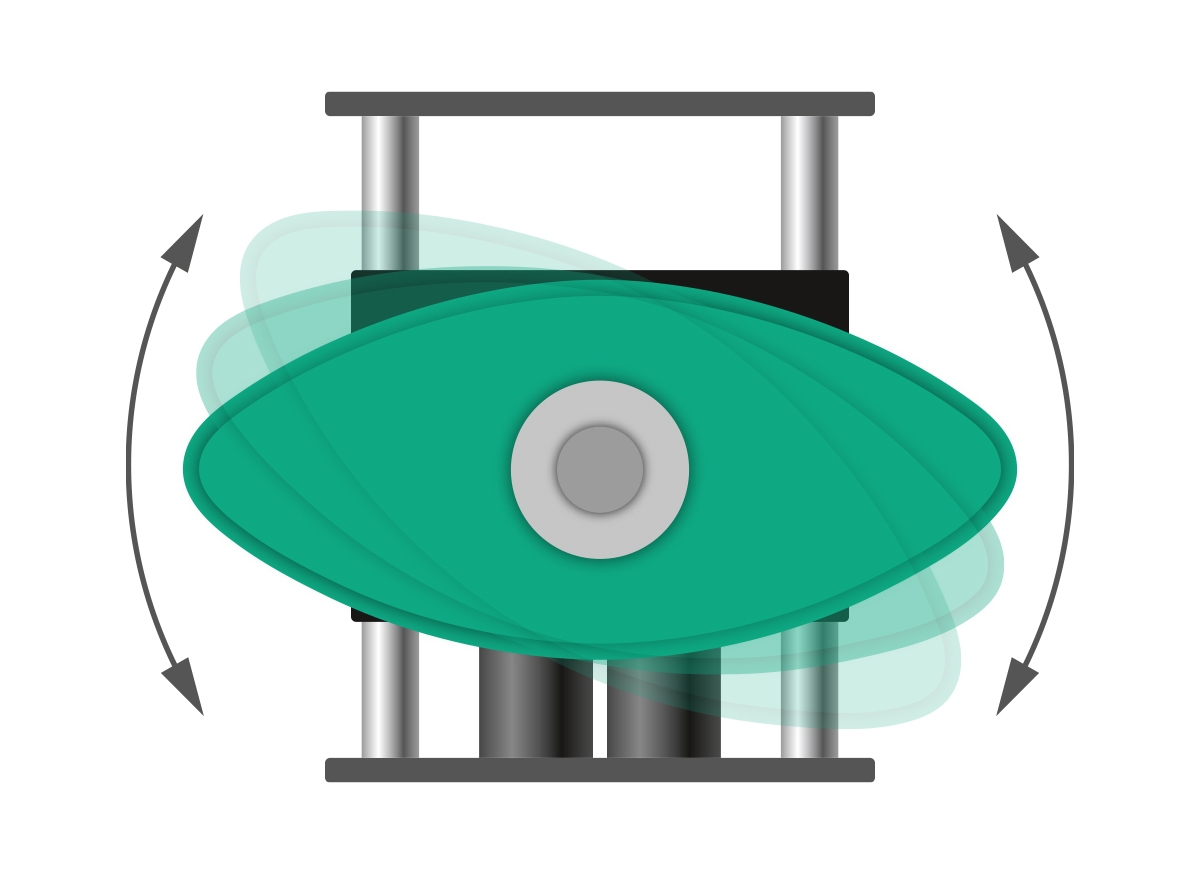

- Elliptical, 180° pivot-mounted chain slide profile made from Original Material "S"®. Greater flexibility in installation and adjustment. Dynamic adjustment in response to increasing chain elongation. Automatic adaptation to chain movement. Slide profile with double the service life without having to dismantle the Spann-Boy® or replace the slide profile. If one side is worn, the profile can simply be turned and the other side used The radius corresponds to a root diameter of 180 mm (twice that of a standard chain tension wheel). Ensures that as many chain rollers as possible are in contact whatever the position of the slide profile. Has a positive impact on the polygon effect.

Areas of use

- Restricted space below the chain. 40 mm is sufficient. Mounting next to the chain possible. Simple mounting remains possible in cases where chain strands run at an angle and installation options are limited. Can be mounted e.g. on horizontal or vertical profiles without additional mounting aids/adapters. Generally speaking: Our tensioning system oscillate freely and are therefore resilient. So they don’t provide a rigid deflection when loaded. This helps avoid excessive contact pressure. The aim is to keep the total force on the slack strand, resulting from the weight of the chain or belt and centrifugal force, under control. The optimal installation position is closely behind the drive sprocket to keep the length of the slack strand to be tensioned as short as possible. Further recommendations and technical information on Murtfeldt’s tensioning systems can be found in the section: Function, concept and handling of tensioning systems.

Application

- For chain drives with changing operating conditions

- For applications where chain drive angles change (e.g. lift tables with external drive)

- Ideal for highly dynamic chain drives

- For control and positioning applications

- For varying centre distances

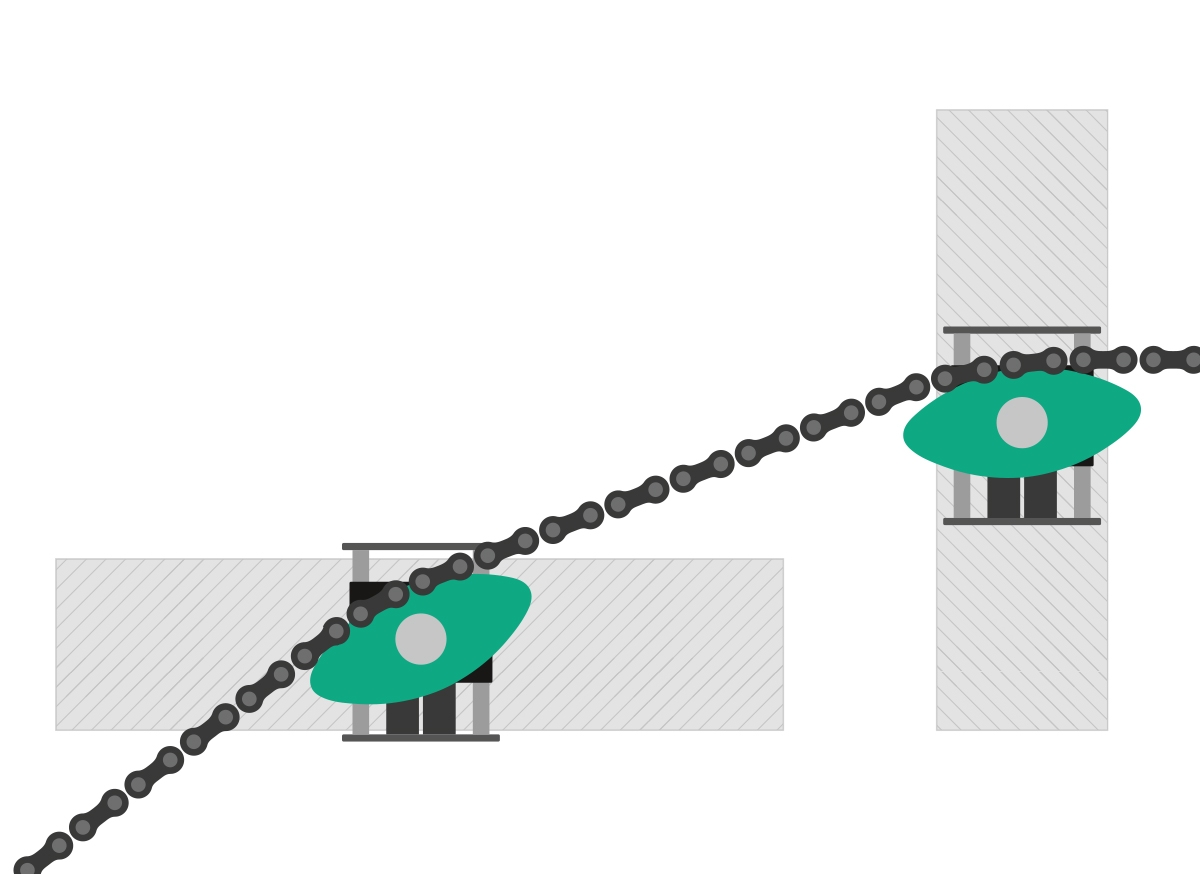

Example application: Spann-Boy® TS-EP

The right chain tensioner for every challenge: lift table example with the Spann-Boy® TS-EP.

The Spann-Boy® TS-EP is specifically designed for use in chain drives with changing operating conditions. Or, more precisely, for applications where chain drive angles change dynamically. The lift table example shown below shows how it all works. When the platform is raised or lowered, the height positions aren’t the only things that change. The position of the slide profile’s angle to the chain strand does too. This means the chain is optimally supported and guided on the slide profile in any operating state. The Spann-Boy® TS-EP is ideal for use with highly dynamic chain drives, in control and positioning applications and with varying centre distances.